CEAGA and six companies from the Cluster have developed a new collaborative project to implement advanced quality control solutions in the automotive sector using artificial intelligence and artificial vision and 3D laser technologies. Its main objective is to guarantee defect-free products, improving efficiency and reducing associated costs. The project, called IA4ZERO DEFECTS II, addresses these challenges with automated systems that enable real-time inspections with high precision.

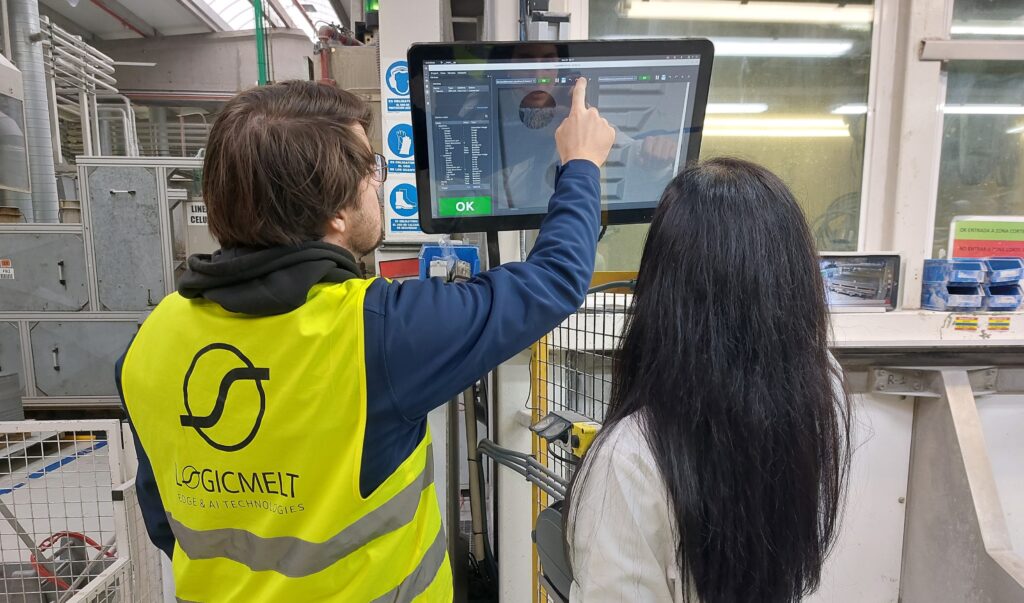

The project, coordinated by CEAGA, involves the companies Unimate Robótica, Logicmelt Technologies, DECUNA, TI Fluid Systems, Componentes de Vehículos de Galicia and Inplasor Galicia. It also has the collaboration of the Digital Innovation Hub Industrial de Galicia (DIHGIGAL).

During the project, specific artificial intelligence models were developed for quality control adapted to different processes and materials, enabling accurate, real-time detection of defects. Innovations were made in the combined use of 2D and 3D cameras together with 3D laser profilometers, technologies that enabled the detection of subtle and complex defects. Edge technology was also implemented for local data processing, reducing latency and improving system efficiency.

Project funded by: